H&R 300 AAC Blackout Handi-Rifle Review

Part 3 - External & Operational Features

May 4, 2013

In this part of my H&R AAC 300 Blackout Handi-Rifle Review, I cover all the external and operational features of the rifle. To start with, the combination of black phosphate finish on the barrel and action along with the black synthetic stock and forend give the rifle a nice look. Throughout the review I may show the rifle on a bipod, but the bipod does not come with the rifle.

These next four photos give you some isometric views of the rifle.

The 300 AAC Blackout Handi-Rifle has an overall length of 29.7".

The stock that comes with the rifle is H&R's youth stock with a length of pull (LOP) of 12". Me being 6' 2", I found it took me a little while to get used to shouldering a stock this short and would have loved for this package to include stock shims to add another inch to the LOP. I think there exists an opportunity for someone to make a little money by providing a grip adapter to allow the use of standard collapsible buttstocks for his rifle. This would allow an adjustable LOP.

The rifle weighed in at 5 pounds just as advertised at the AAC website. I believe a typo exists in the 2013 catalogue where they state a weight of 6.9 pounds.

The barrel comes threaded with a 5/8"-24 TPI thread measuring 0.62" in length. The end of the barrel has a slight bevel crown and comes with an aluminum anodized thread protector.

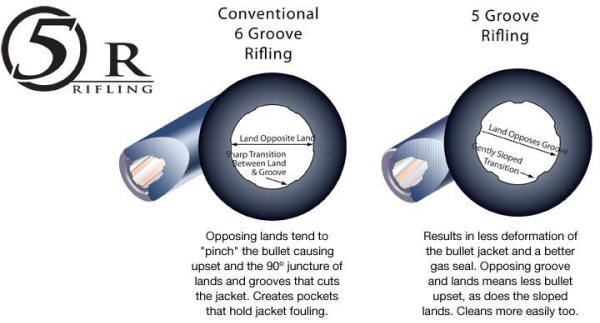

The barrel has 5R rifling which is advertised that it results in less deformation of the bullet jacket and produces a better gas seal. I have some other rifles with this same rifling and have been pleased with the results.

Figure 12

The barrel measured 16.31" which is slightly longer the the 16.1" advertised at the AAC website. The barrel has a light weight profile. The diameter measured 0.65" rear of the flare at the end near the thread protector and about 0.71" at the midpoint.

The barrel comes drilled and tapped with a Picatinny styled optics rail mount already installed. The front 40% of the Picatinny rail is cantilevered over the barrel and is unsupported.

The forend is held in place by a single screw and the forend has a steel sling swivel stud installed. A nice touch would have been to provide the rifle with some type of knurled ended screws so you could takedown the rifle without any tools.

The forend has a textured surface that gets rid of the slick feel you get from some polymer forends.

Because the rail mount is cantilevered over the barrel, the three rear attachment screws are in the rear half of the mount.

Before I ever install an optic, I first check the solidness of the mount and tightness of the screws. I first checked the fit with a feeler gauge and was able to get an .002 blade part way under the entire perimeter of the mount. This lets me know that the mount and receiver are making contact mainly near the middle of the mount. Next I checked the torque and the fasteners appeared to have only about 10 in-lbs of torque.

I removed the mount and found there to be a lot of oil underneath and there was some type of thread locking compound in the screws holes.

Because I know the importance of starting with a good foundation when mounting optics, I thoroughly cleaned all components and bedded the mount to the receiver as shown below. After bedding, I then reinstalled the screws with thread locking compound (purple) and torqued the screws to 18 in-lbs. If you do nothing else, I recommend removing your mount and thoroughly cleaning all the surfaces and screw holes with some type of solvent. Next reinstall your screws with some type of thread locking compound (purple which is designed for this size thread or blue at the most) and torque the screws to at least 15 in-lbs.

The controls for the Handi-Rifle are simple. The rifle has a hammer, trigger and release lever.

The right side of the barrel is marked with a generic WARNING. The right side of the receiver has engraved the AAC logo and "AAC". I feel that the engraving of these items could have been a little deeper because they barely stand out depending on the lighting.

The rifle includes a solid steel trigger and the trigger pull averaged 4.82 pounds based on 10 pulls using a Lyman Digital Trigger Pulls Scale. I couldn't detect any creep and the trigger seemed to break crisp at this pull weight, although there was noticeable overtravel.

The trigger guard is made from some type of black polymer (synthetic) material and there were no markings on the lower portion of the receiver.

The left side of the barrel and receiver were marked as shown below.

The barrel is marked "HANDI-RIFLE", "300 AAC BLACKOUT 1:7" and includes a date stamp "BH" which I think means January 2013 and an oval proof mark with "REP" on the inside. The receiver is marked "HARRINGTON & RICHARDSON", "MANUFACTURED IN ILION, NY U.S.A" and with the serial number.

This next photo shows the hammer in the uncocked (forward) position and the cocked (rear) position. You can see that in the cocked position the transfer bar has moved into the up position which will allow the hammer to contact the firing pin when the trigger is pulled. When the hammer is uncocked, the transfer bar is in the down position and there is no way striking the hammer will cause the rifle to fire.

The 300 AAC Blackout Handi-Rifle comes with a short youth style black polymer stock.

The length of pull on this rifle measured 12". The rubber recoil pad is relatively firm in the center, but vented areas on each side help it to conform to your shoulder. The stock contains the same texturing as the forend and provides a nice no-slip feel.

The bottom of the stock has a rear sling swivel stud and a cap at the bottom of the grip area.

The rear of the recoil pad contains the New England Firearms logo "NEF".

To open the action, you press the release lever and push down on the barrel/forend while holding the grip and the rifle will break open as shown below. The release lever rattles a slight amount in the receiver.

One of the first things you will notice is how thick the barrel is around the chamber. I believe that this extra thickness has to do with H&R standardizing their receiver and barrel blanks to accommodate much larger calibers.

When you insert a cartridge into the chamber, you see that the extractor pushes up on the cartridge. When the cartridge is inserted fully into the chamber, the rear of the cartridge sticks out as shown below.

As you close the action, the extractor pushes against the breach face and doing this pushes the cartridge the remainder of the way into the chamber.

The extractor is not spring loaded and you will have to pull the fired case from the chamber by hand.

Thoughts

Overall, I like the fit and finish of the 300 AAC Blackout Handi-Rifle. I feel that a little TLC is always needed to ensure your optic mounts have the best integrity possible and that was the case on this rifle and typically most rifles. The release lever rattles some, but other than that, I like this shooting platform.

For more detailed photos and commentary, make sure you check out the other parts of this review and feel free to leave comments on my Reader's Comments page. The following links are provided to help you see other parts of this review.

- H&R 300 AAC Blackout Handi-Rifle Review: Part 1 - Introduction, Specifications and Summary

- H&R 300 AAC Blackout Handi-Rifle Review: Part 2 - What's in the Box

- H&R 300 AAC Blackout Handi-Rifle Review: Part 3 - External and Operational Features (this page)

- H&R 300 AAC Blackout Handi-Rifle Review: Part 4 - Disassembly

- H&R 300 AAC Blackout Handi-Rifle Review: Part 5 - Internal Features

- H&R 300 AAC Blackout Handi-Rifle Review: Part 6 - Range Test

Or

If you would like to be notified about future Gunsumer Reports reviews via Facebook, make sure "You Like This" by clicking the Facebook "Like" button at the bottom or top of this page. If it already says "You Like This" beside the button, clicking it again will uncheck the "Like" status and you will not be notified.

| Share on Facebook | |

© 2010, 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018, 2019, 2020, 2021, 2022, 2023 & 2024 Gunsumer Reports™, All rights reserved.

FTC Disclosure